Designing a fast, low-cost method to estimate sensory shelf life of fresh produce

A case study on designing a fast, low-cost, image-based method to estimate sensory shelf life of fresh produce using survival analysis and remote consumer testing.

—The challenge—

Determining sensory shelf life is critical for fresh produce, but traditional consumer tests are slow and expensive as they require:

Recruiting large consumer panels to gather meaningful amounts of data

Bringing participants on-site and coordinating facilities, staff, and scheduling

Providing financial incentives

For example, if a study requires 100 consumers and each receives a $10 gift card, that represents $1,000 in incentives alone, not including labor and facility costs. For fast-moving or early-stage product decisions, this approach is often impractical.

—My approach—

Because consumer acceptance of fresh produce is driven primarily by visual appearance, I reasoned that in-person testing might not be necessary, and that instead a photograph could be sufficient. This opens the door for a remote, image-based sensory approach that can dramatically reduce cost and turnaround time.

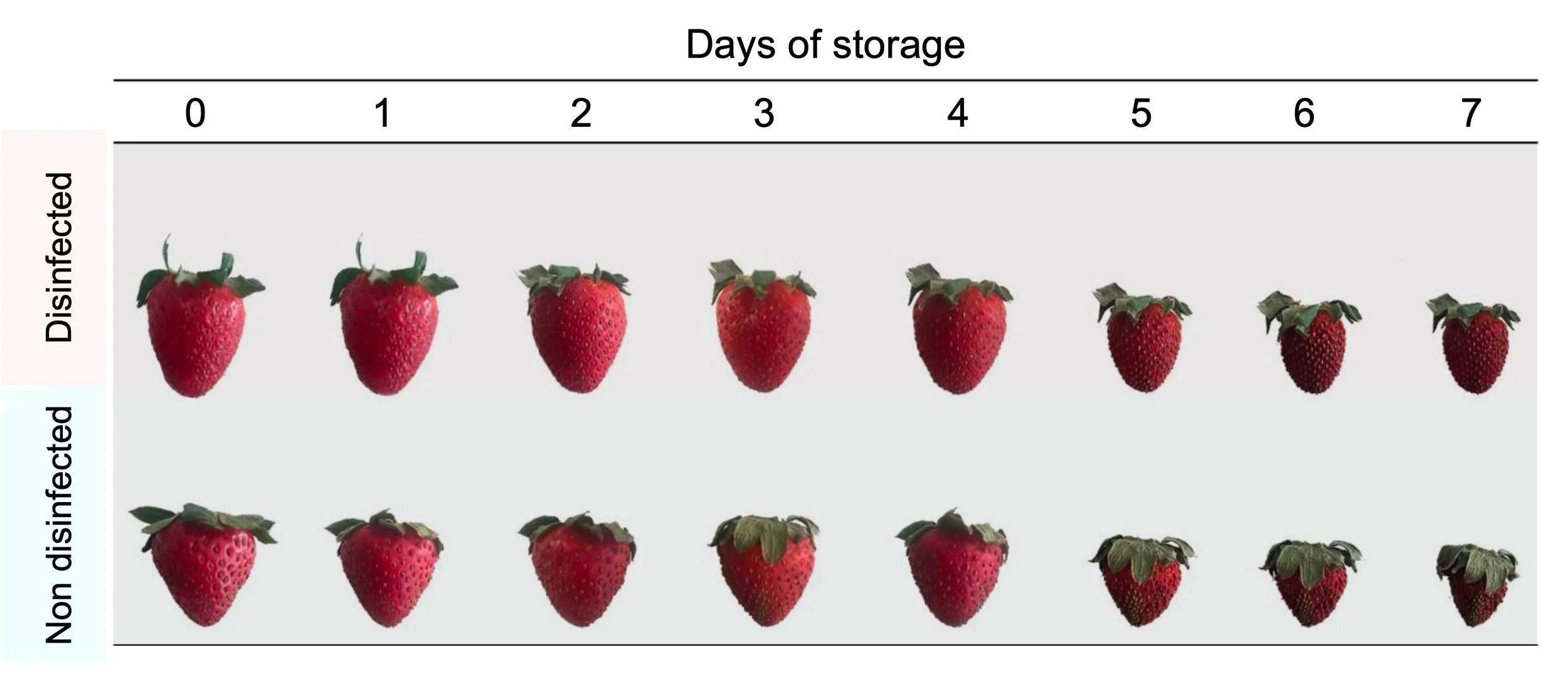

I used strawberries as a model system due to their short shelf life and visual sensitivity to deterioration. For the study I:

Designed a paired experiment comparing disinfected vs. non-disinfected strawberries

Applied a simple 10-minute disinfection step (Microdyn)

Stored samples under refrigerated conditions for 7 days

Collected daily standardized photographs of each sample as shown below

Using these images, I built an online survey where:

Each image was shown randomly

Consumers were blinded to treatment and storage time

The only question asked was:

“Would you consume this strawberry?”

In just 36 hours, I collected responses from 182 consumers (62% female).

—Key results & impact—

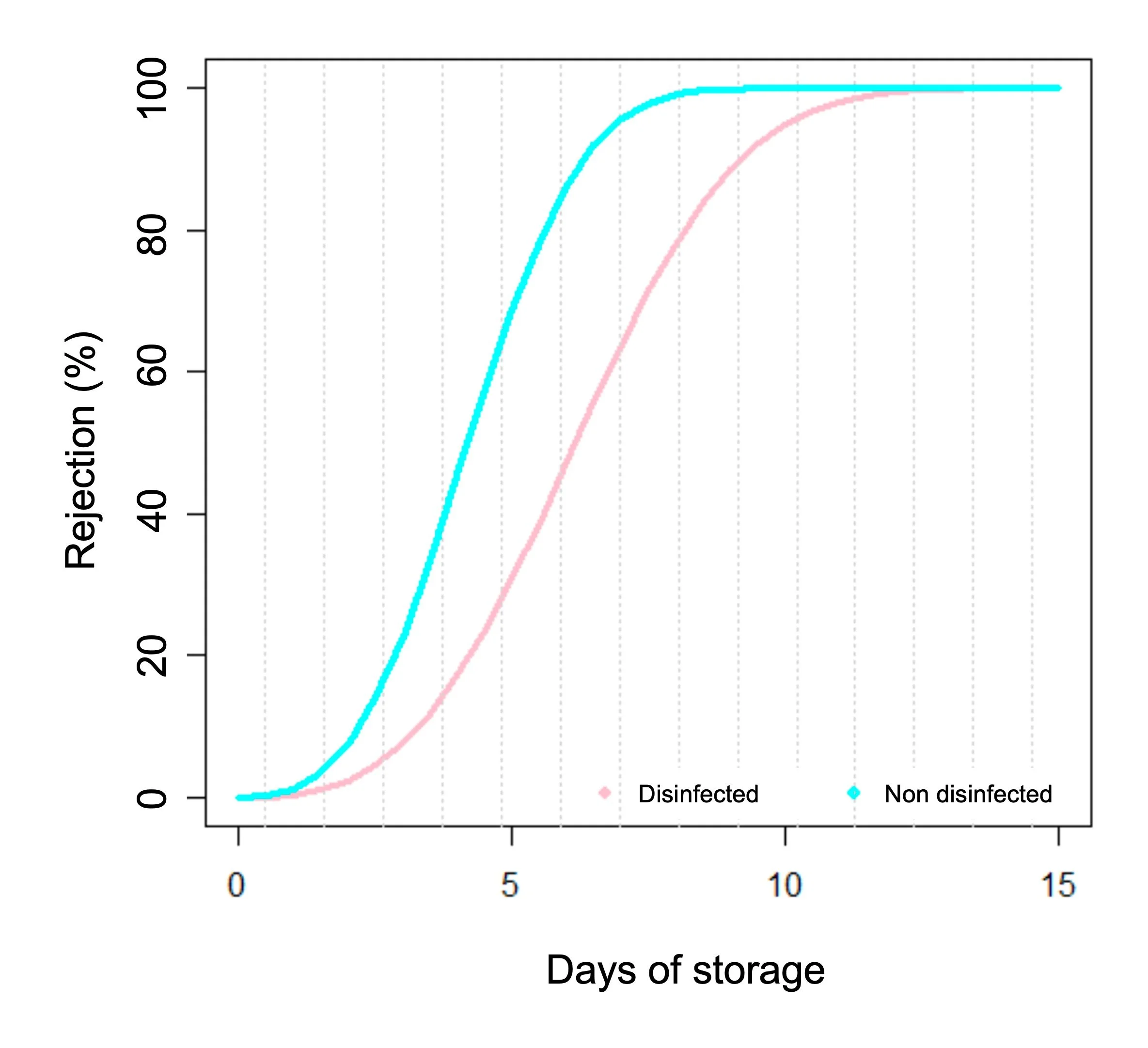

Using survival analysis, I constructed rejection curves for both treatments and defined shelf life as the time at which 60% of consumers reject the product (an operational threshold that can be adjusted based on product type, economic constraints, distribution strategy, etc.).

Result: the sensory shelf life was

Non-disinfected strawberries: ~5 days

Disinfected strawberries: ~7 days

In other words, a simple 10-minute disinfection step extended sensory shelf life by ~2 days.

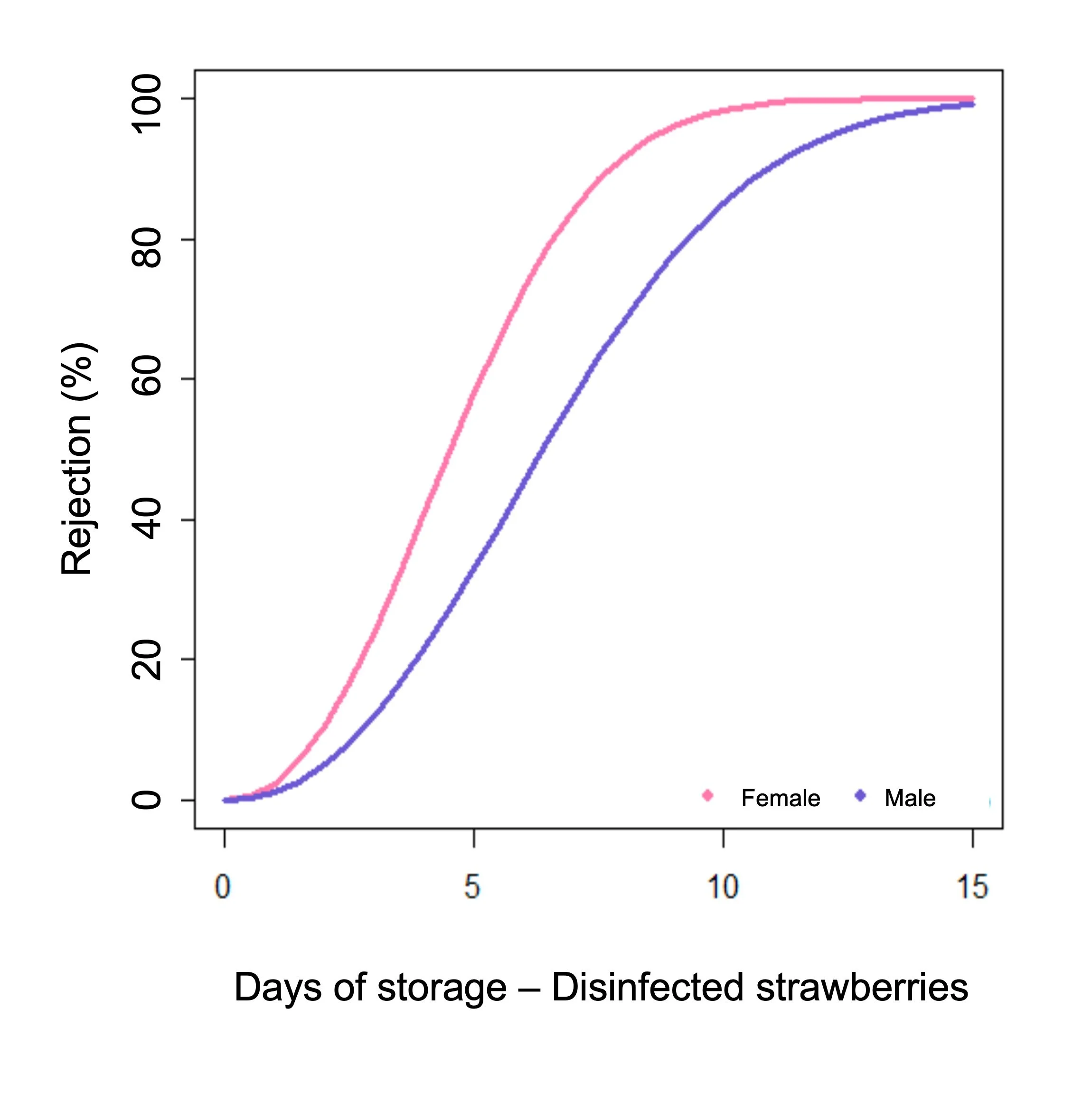

By collecting basic demographics (gender, age, consumption frequency), I also evaluated how consumer segments influenced rejection behavior. The insights obtained were:

Gender significantly affected rejection behavior for disinfected strawberries

Female consumers rejected the product earlier than male consumers

In the industry, these types of insights can directly inform:

Target market selection

Labeling and positioning

Shelf-life claims and risk management

Effect on desinfection on the shelf life of fresh strawberries stored under refrigeration conditions.

Effect of consumer’s gender on the shelf life of fresh strawberries stored under refrigeration conditions.

“This case study demonstrated that a remote, image-based method can reliably estimate sensory shelf life and that shelf-life differences between treatments can be quantified quickly and at low cost”

—Industry relevance—

This project demonstrates a scalable, low-cost strategy for:

Rapid shelf-life screening of fresh produce

Comparing processing or sanitation treatments

Early-stage product decisions before investing in full sensory panels

Potential applications include:

Fresh produce processors

R&D screening pipelines

QA and shelf-life optimization teams

Cost reduction in sensory programs

Interested in how this approach could apply to your products? Let’s chat.